E-Sharp News

November 2019

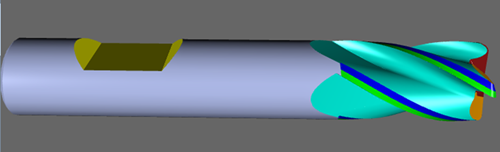

Do you think the use of a Weldon flat on the shank of a cutting tool is old technology? Well read on as it may not be as clear cut as you think. Firstly, let’s start by explaining what a Weldon flat is. A Weldon flat is a flat section on a tool shank. When placed in a Toolholder the flat on the shank is held in place by set screws within the body of the holder. Using this flat, a set screw securely holds the tool and prevents the tool from rotating when machining. Weldon flat tools are predominately used when milling but can be used in other applications.

Why use a tool with a Weldon Flat?. Because of the extreme forces involved in machining titanium and other hard metals, pullout” can be a problem. Pull out is the tendency for a cutting tool to gradually loosen in its holder and twist out completely. When using an endmill with a high helix (above 50°) the material engages that helix and creates an axial force that tries to pull the tool out of the holder. The higher the helix angle the more axial force is created, and the possibility of pullout is increased.

When rough machining and removing large amounts of material, Weldon flat holders can be beneficial. Particularly in the Aerospace sector when machining parts such as expensive wing spars, tool pullout can occur which can be very costly and damaging. When machining materials such as Titanium, optimal machining parameters produce high torque forces on the cutter, Titanium requires an aggressive depth of cut at relatively slow spindle speeds and Weldon Flat holders are ideal for these types of applications.

However, Weldon Flat tools do have their disadvantages. Weldon-style endmill holders by their design push the cutter off centre which creates runout and can drastically reduce tool life. Tool Balancing (or imbalance) can also be a problem. Many high-end Machine tool builders state on their machines only “balanced tooling” can be used so it is critical that the Weldon Flat Toolholders are balanced correctly before use. In many scenarios a run out of under 0.010mm is not possible when using Weldon flat tooling.

Weldon Flat holders and shank tools with flats still have their place in the modern machine shop. Although companies will have to purchase a wide range of toolholders dependent on the application and material to be cut. To manage this large range of applications some Toolholder manufacturers have developed combination tool adaptors (Hydraulic and shrink fit variations) for Weldon flats, which provide anti pullout characteristics. These combination toolholders can be perfectly balanced and maintain low run out. Combination holders provide a solution to companies who want to use Weldon flat tooling and the one of the reasons that flats on shank tools are still in demand.

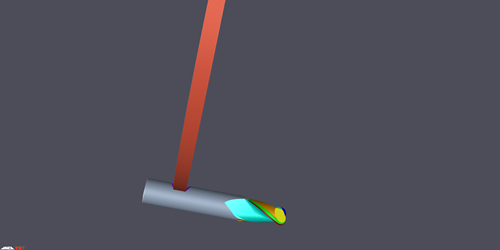

But did you know that ANCA grinding machines come standard with the software for grinding Weldon flats? ANCA ToolRoom software has dedicated software not only for grinding of Weldon Flats but also for Tool balancing to ensure outstanding grinding results which enables

our customers to produce tools for all applications.

19 November 2019