E-Sharp News

June 2020

“Recent updates released to market for the dressing software in ToolRoom helps customers to reduce cycle time while dressing from solid and increases productivity in the manufacture of cutting tools” Thomson Mathew, Software Product Manager.

Time is money and any improvements in cycle time increases productivity and in return increases profitability. Responding to customers, looking for solutions to optimise grinding cycles for their production needs; ANCA recently delivered a tailored dressing solution in a software update with

optimised dressing from solid by removal of air passes. Thanks to our experienced software engineering team, this intelligent solution can help customers improve and streamline their production processes. Applications like tap, punch, key hole punch and drill require a lot of in-process dressing on the machine and customers will benefit significantly in terms of time and cost from this new software feature.

Implementing optimised dressing is a highly technical solution made easy

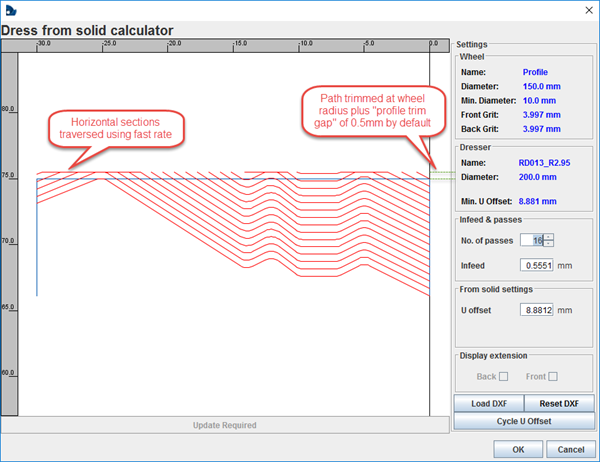

In the existing implementation of solid dressing, the final wheel profile is offset in the radial direction such that the first pass only dresses the wheel by the specified infeed per pass. This method results in a significant amount of dressing in air, where the dresser roll is not in contact with the grinding wheel as shown below. A particular customer request was to find a solution to reduce solid dressing cycle time.

The solution was implemented by trimming sections of the dressing path which lie above the wheel radius and increasing the feedrate of moves where the roll is not in contact with the grinding wheel as shown below.

This update is compatible with any machines with ToolRoom RN33.2 release onwards and has wheel dressing capability. This feature is available for all solid dressing surface types which includes form, periphery and segment dressing. Optimised dressing has replaced the existing implementation of dressing which will no longer be available due to the longer cycle times. Optimisations will automatically be calculated for dressing a profile onto a new or flat profile wheel and only air dressing beyond the wheel radius will be optimised.

The update with the above optimisations can be utilised in many applications specially taps, punches, and key hole punches.

Dressing software is in-process, customisable and easy to use

The dressing software allows in-process dressing of standard and profile wheels via a dresser mounted inside the machine. The software supports up to two dresser units built into the machine. Dressing of standard or complex profile forms is greatly simplified using the intuitive user interface. Various options exist to customise the dressing process, including the ability to specify dressing segments on the wheel.

Plunge dressing using special formed rolls is also supported. Calculators are provided to simplify parameter input. The dressing software allows dressing of any possible wheel shape provided the process is physically possible. All the above are supported with AEMS (acoustic emission monitoring system) where dressing using a diamond roll on a diamond wheel is possible.

Image of headstock dressing on an ANCA machine

Flexible options for automatic white-sticking

Autostick software enables the automatic white-sticking option within the dresser software. This allows automatic sticking of grinding wheels. The sticking process is easily configured using the dressing software so that sticking can be performed as part of, or separately from a dressing operation.

This software requires a white-stick fixture to be present within the machine. This feature is supported on the FX, MX and TX range of ANCA Tool and Cutter Grinding Machines. Some machines even have the option to have up to four dressing sticks.

Image of white-stick application on an ANCA machine

27 May 2020