E-Sharp News

March 2020

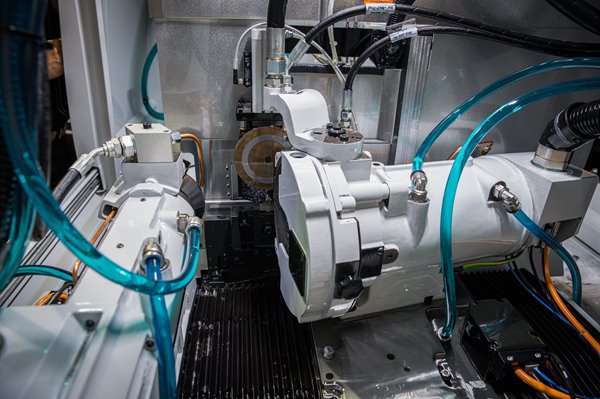

Preparing tool blanks before grinding on a tool and cutter grinder is an important part of the process for companies making cutting tools. Manufacturing precision blanks to close tolerances reduces bottlenecks and can limit the time spent producing the finished tool on a grinding machine.

Address the challenges of temperature variation for precision tool blank grinding

Address the challenges of temperature variation for precision tool blank grinding

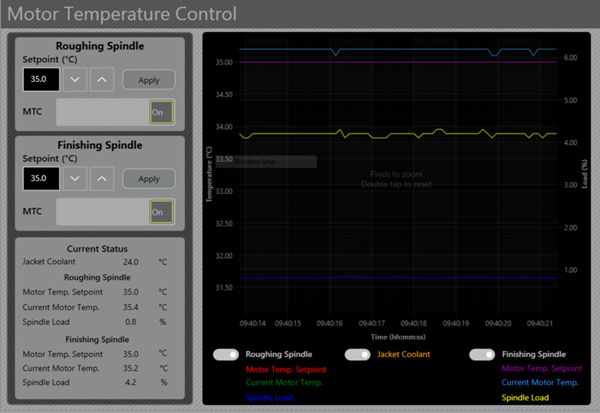

When grinding, maintaining machine temperature over time is critical for tool grinders to ensure micron accuracy on the finished part. During grinding the spindle undergoes a lot of fluctuating temperatures. To combat varying temperatures and reduce thermal instability, ANCA has implemented as standard on the CPX Linear for both roughing and finishing spindles a new feature called Motor Temperature Control (MTC).

MTC (patent pending) monitors and maintains the operator set spindle temperature which provides the benefit of minimising the spindle axial growth. This makes the CPX extremely accurate and reduces dimensional changes on the blank ensuring consistent results. The CPX machine still needs to be warmed up for a predetermined period, but the warm up time is shorter, and spindle growth is diminished. The brilliance of MTC is that no extra components are required to realise the benefits this product can give. Smart algorithms built into the spindle drive firmware are the secret to keeping the spindle motor running at a constant temperature.

MTC’s constant operating temperature offers productivity gains and quality improvements

MTC’s constant operating temperature offers productivity gains and quality improvements

MTC ensures the temperature of the spindle motor remains stable even when the RPM and loads vary during grinding. For example, when grinding tool blanks and removing large amounts of material, the roughing spindle can become hot. Using MTC this problem is no longer a concern as the spindle temperature is set by the operator and managed for optimal performance and grinding conditions. Maintaining thermal stability improves machine energy efficiency, delivering incremental reductions in the running costs of the machine tool.

The CPX machine reaches thermal stability more quickly, meaning production can start sooner - increasing productivity and limiting costly downtime. Additionally, improved product consistency means tool blank quality improves and fewer blanks are rejected and out of tolerance.

ANCA Product Manager, Simon Richardson said: “MTC is a unique and innovative product providing a ‘step change’ in the way machine temperature is maintained when grinding and gives the user greater control over the process. The ANCA CPX Linear with MTC provides customers with the most accurate and thermally stable blank grinding machine on the market today.”

13 March 2020