E-Sharp News

March 2025

Get the powerful Feedrate Optimization feature FREE when you upgrade to ToolRoom RN35. Act fast—this offer expires with the upcoming software maintenance release!

The Feedrate Optimisation feature in ANCA’s latest ToolRoom RN35 software seamlessly integrates material removal rate (Q) and specific material removal rate (Q’) into iGrind operations, allowing users to automatically optimise feedrates. This results in improved cycle times, extended wheel life, and enhanced tool quality. By leveraging the Feedrate Optimisation Wizard, customers can achieve a constant material removal rate while minimising unnecessary air grinding, leading to even greater productivity.

Key benefits of Feedrate Optimisation include:

- Optimised and reduced cycle times

- Improved wheel life and efficiency

- Uniform wheel wear for consistent grinding performance

- Increased grinding productivity between wheel reconditioning and replacement

- Stable and enhanced tool quality

Precision at your fingertips

Feedrate Optimisation Wizard

Feedrate Optimisation Wizard

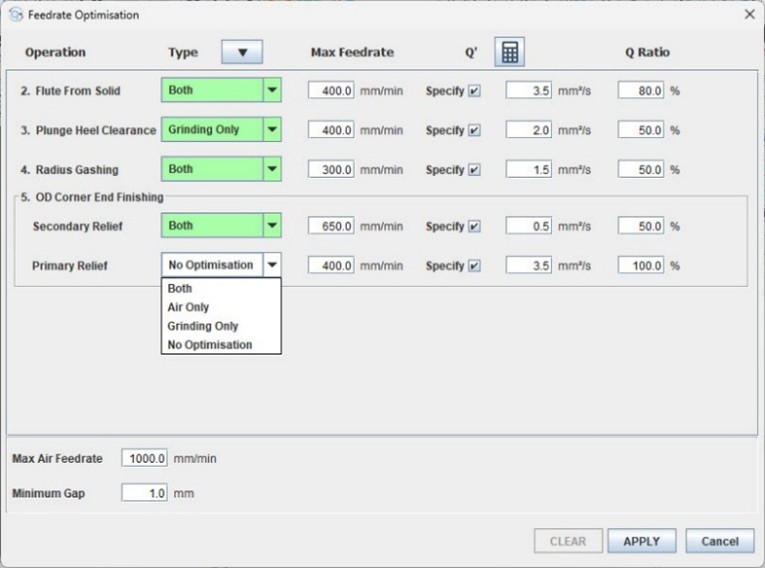

The Feedrate Optimisation Wizard is accessible from the toolbar or tool menu, guiding users to calculate the optimal feedrate curve for each move based on key parameters. Users can control the material removal rate (via Aggression %) and specific material removal rate (Q’) to optimise performance without compromising wheel integrity.

- Q (Material Removal Rate): The volume of material removed per unit time, measured in cubic millimetres per second (mm³/s).

- Q’ (Specific Material Removal Rate): The material removal rate normalised by the grinding wheel width, indicating grinding intensity.

Feedrate Optimisation calculates and adjusts feedrates while maintaining defined limits for Q and Q’. This prevents excessive wear, preserves profile geometry, and ensures consistent tool quality.

Feedrate Optimisation applies to both roughing and finishing moves, but variations in feedrate may impact surface finish. To maximise benefits without affecting surface finish, users can apply optimisation exclusively to roughing moves while skipping finishing operations. Sparkout moves remain unaffected to ensure the required surface quality.

Optimised feedrate curve display

The optimised grinding cycle adjusts feedrates based on different move types:

- Air Moves: Movements that do not contact the workpiece

- Maximum Feedrate: The highest feedrate for a grinding move

- Max Air Feedrate: The maximum feedrate for an air move

- Minimum Gap: A predefined gap before contacting the workpiece, ensuring controlled feedrate transition

The system provides a side-by-side comparison of cycle time improvements between standard and optimised settings, allowing users to visualise time savings achieved through Feedrate Optimisation.

Cycletime comparison of a 12mm 4 flute corner radius tool

ToolRoom RN35: More than just Feedrate Optimisation

ToolRoom RN35 includes a range of additional features designed to enhance user experience, boost productivity, and minimise cycle times. With advanced automation and efficiency-driven tools, this latest release empowers users to achieve greater grinding precision while maintaining cost-effectiveness.

With Feedrate Optimisation and other performance-enhancing features, ToolRoom RN35 ensures manufacturers achieve higher productivity with every tool.

Watch our Tool Tip Tuesday series on Feedrate Optimisation:

11 March 2025