E-Sharp News

October 2020

Medical manufacturing company, Straits Orthopaedic, deliver on diverse medical applications with their flexible ANCA CNC grinding machines.

If manufacturers have learned anything over recent months, its that you can take nothing for granted. Circumstances can change quickly and how you are set up to respond can be the difference between your business flourishing or folding. Recognising this, Straits Orthopaedic has been investing in ANCA machines as part of their strategy to be a flexible manufacturer in the medical tooling and component market.

The events of COVID-19 this year are perhaps the most extreme example of rapid market change and resulting uncertainty. But, even after more normal circumstances return, manufacturers need to be constantly vigilant, watching and responding to changes in the market that provide new opportunities or necessitate a pivot in their business.

ANCA CNC grinding machines have long been recognised in the industry for their flexibility. It is this kind of flexibility that allows ANCA users to produce parts for diverse applications, so they are not limited to just one customer or one application. Powerful software allows users to create programs for a broad range of cutting tools and components. While modular machine design means features can be easily configured to suit the varying needs of different applications.

The medical industry offers exceptional and diverse opportunities for manufacturers, with ANCA grinding machines supporting international markets in the production of complex bone rasps, long rotary reamers and tiny dental drills and burrs – just to name a few.

Straits Orthopaedics, based out of Malaysia, is a case-in-point of a company taking advantage of ANCA’s diverse capabilities. Already well established for contract manufacture of medical components, Straits Orthopaedics’ first tool grinder was an ANCA FX5. Senior Process Development Engineer, Vidyadhiraj Vidyadharan comments: “Custom made tools have become a significant part of our growth in the medical tool market. We need the ability to make special tools to varying customer requirements and to be able to do it quickly. ANCA’s FX5 with its flexible tool programming software has certainly allowed us to meet this need. Demand for our diverse range of medical drills, reamers and planers easily justified our second FX5.”

;.aspx?width=300&height=650)

Diverse grinding applications at Straits Orthopaedic

As their business has grown, Straits Orthopaedic could see other market opportunities they wanted to pursue, and decided on a TX7 Linear for their next investment. This was a proactive move to demonstrate production capability to several different customer applications. In particular, Straits was chasing opportunities for hip rasp manufacture, and at the same time larger, longer orthopaedic reamers – two very different applications. Hip rasps have complex programming requirements done in a CAD-CAM environment and are ground with between centre work holding. Orthopaedic reamers, on the other hand, are long and thin, and require flexible tool support options to avoid tool deflection and vibration during production.

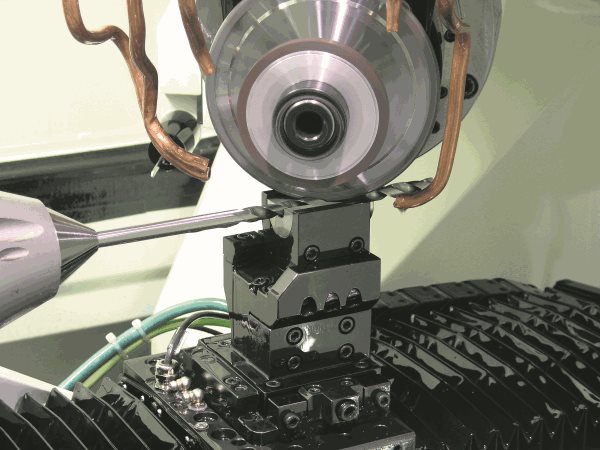

On the TX7, Straits requested the addition of the P-axis travelling steady option.This feature was essential to give tool support options for both applications. Part of the machine acceptance required ANCA engineers to demonstrate how it could be quickly configured from a fixed tailstock to suit the hip rasp application, to a travelling tool support that could cover the needs of a long thin reamer.

Tool support is essential for grinding longer medical tools

A CNC dresser was also part of the Straits’ machine package. Grinding medical stainless is a challenge as it is ‘sticky’ and ends up clogging the wheel which no longer cuts freely. However, developments with vitrified bond CBN grinding wheels is proving to be a welcome development. The TX7’s in-built CNC dresser means these wheels can be re-dressed as required to ensure correct wheel profile is maintained and the grinding grit is kept open for free cutting.

The other decision point was programming capability. With experience grinding rotary cutting tools on the FX5 machines, Straits were already confident that the TX7 it would easily cover the reamer applications they were chasing. But rasp manufacture was a different proposition. As complex 3D parts, they require a CAD-CAM programming environment. ANCA supports this with their own ANCam software, that operates in the Siemens-NX environment.

ANCA's CIM3D software validates the grinding process before starting on the machine

ANCam offers a distinct advantage by allowing machine operators to make program adjustments on the machine without needing this to be done in the CAD-CAM programming environment. Additionally, ANCA’s CIM3D software allows programmers to view and validate the entire grinding program before actual grinding starts on the machine. Not only can the tool geometry be checked, but also grinding wheel collisions with workpiece tooling can be identified and eliminated.

Importantly for Straits Orthopaedic, ANCA was able to support them in developing programs for their first rasp designs produced as part of their bid to secure contracts for making these complex parts.

Straits has been able to take full advantage of the diversity in machines and capability offered by ANCA, and in doing so set themselves up to ensure they can take on new opportunities in the market for future growth.

27 October 2020