In one year, 125 tonnes of carbide are turned into 2.5 million high-quality precision tool blanks of all kinds - PREMEX masters this diversity like no other.

The manufacturer of semi-finished carbide products processes around 65,000 orders a year and has organised its production in such a way that it meets the highest standards of quality, delivery reliability and flexibility. This requires, among other things, the best equipment in terms of machines for blank processing, especially when it comes to special segments such as gear skiving, in order to meet the growing demand from the automotive, robotics and aerospace sectors.

And when ANCA, a manufacturer that has made skiving expertise a core area, is involved, nothing stands in the way of entering this promising technology.

"We see ourselves as a link between carbide manufacturers and tool grinding shops and aim to continuously expand our leading position," says Marc Huser, Managing Director of PREMEX GmbH from Remchingen-Wilferdingen between Pforzheim and Karlsruhe. This claim is based on a competent and motivated workforce, a lean philosophy that is practised on a daily basis and consistently high quality standards.

"The core requirement and at the same time a distinguishing feature is the large number of daily enquiries and variety of items requested, which we can fulfil quickly and flawlessly. Our entry into the skiving segment fits in perfectly with this," explains Huser.

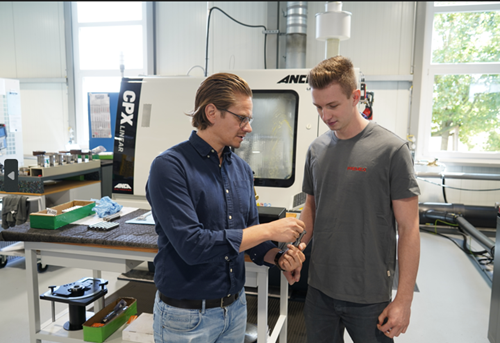

Marc Huser in front of the ANCA CPX with Dennis Roser, Sales Engineer at PREMEX

Marc Huser in front of the ANCA CPX with Dennis Roser, Sales Engineer at PREMEX

One component of this is the further training of the workforce, which is pursued beyond training throughout the entire period of employment. Another important aspect is listening to the market, combined with a positive attitude and continuous strategic development of the portfolio.

"We want to support our customers in their business by accompanying new developments on our part and supporting them with the necessary expertise and the corresponding production capacities." With this in mind, PREMEX has invested in a CPX blank processing machine from ANCA, which not only makes production in general more flexible, but also paves the way into the specialised world of gear skiving.

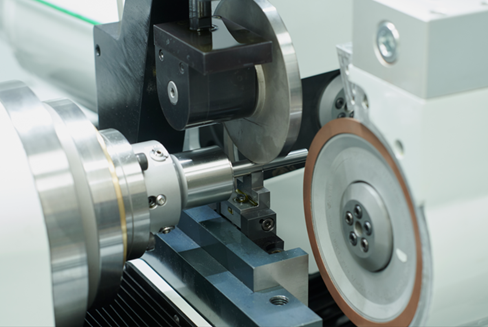

"Like PREMEX, ANCA is an innovation- and market-driven company. Our CPX was developed in dialogue with users who were emphatically demanding a machine for blank processing that is tailored to their needs. Productivity, quality and ergonomics were at the centre of the development and the result is a powerful machine that is already extensively equipped as standard, ensuring highly accurate results even in unattended production as well as high process and operational reliability," says Santosh Plakkat, Product Manager at ANCA. "Our proprietary BlankX software, MTC (Motor Temperature Control) and automatic disc wear compensation are standard features that make the CPX an asset to any manufacturing operation."

ANCA’s CPX Linear is tailored to the requirements of blank processing

ANCA’s CPX Linear is tailored to the requirements of blank processing

Marc Huser confirms this: "With its good removal rate and high loading capacity, the CPX is a real asset to our business, especially for blanks in the medium and larger diameter range. Thanks to the user-friendly interface, our grinders were able to familiarise themselves with the product in a short time and work effectively with it. The ANCA team has always shown great motivation and interest in supporting us."

Vadim Zaiser, ANCA Product Manager for Gear Cutting Tools, emphasises this proactive approach: "Just as the CPX is a response to the needs of blank manufacturers, we also looked at the gear cutting tools segment. There was a development here in connection with changes in the requirements for end products that we wanted to develop an answer to."

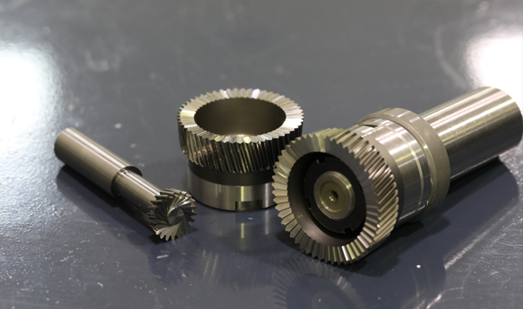

In sectors such as the automotive industry, particularly for planetary gears for electric cars, as well as aviation and robotics, the requirements for gears have evolved to such an extent that skiving has become the preferred gear cutting technology. Internal gears and shafts with interfering contours and multiple teeth can be produced most efficiently using skiving tools. Demand is high and, according to ANCA, will continue to increase.

It is precisely these trends that a manufacturer like PREMEX can pick up on in order to quickly supply the precision tool industry with high-quality blanks.

Skiving is the gear cutting technology that is increasingly in demand in many industries, as it is the most efficient way to machine complex internal gears and shafts subject to interference.

Skiving is the gear cutting technology that is increasingly in demand in many industries, as it is the most efficient way to machine complex internal gears and shafts subject to interference."Skiving is currently one of the most exciting segments in our market. ANCA has developed a great deal of expertise in this area and has also successfully positioned a corresponding machine with its GCX series," says Huser. "We are happy to use this expertise to supply the corresponding blanks as an important part of the process chain for high-quality skiving and perfect gearing."

"As a manufacturer of carbide semi-finished products, we are very interested in this market, as our core portfolio is also very well suited to producing blanks for the manufacture of various modules in the gear cutting industry. Thanks to the successfully completed project between ANCA and PREMEX GmbH in the field of power skiving, we are now in a position to offer blanks for gear cutting tool manufacturers."

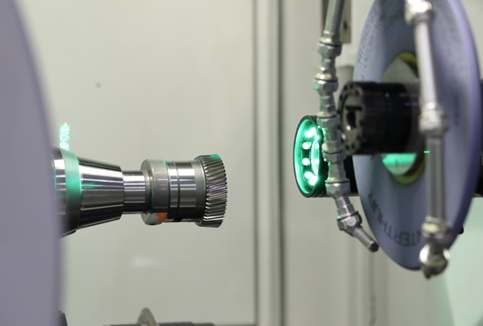

A decisive aspect in the manufacture of skiving tools is the closed loop measurement in the process, which ensures quality and avoids rejects.

A decisive aspect in the manufacture of skiving tools is the closed loop measurement in the process, which ensures quality and avoids rejects.