E-Sharp News

November 2013

Precorp, an ANCA customer in the United States, is gaining the benefits of a partnership designed to bring new technology to the production of PCD tooling.

Aerospace & Automotive are driving development of new materials

Demands from the aerospace and automotive industries for more efficient and light-weight products are driving the development of new and exotic materials. As these become more advanced, they are challenging traditional manufacturing methods and driving advances in cutting-tool substrate and design. Industries such as aerospace and automotive are increasingly using materials such as Carbon Fibre Reinforced Plastic (CFRP) that offer advantages in performance and fuel efficiency. A result of this trend is the increasing demand for Polycrystalline Diamond (PCD) cutting tools.

For tool manufacturers looking to enter this growing market, ANCA now offers the new EDGe erosion and tool grinding machine which is an innovative solution for the production of PCD tooling. The EDGe machine is ideal for PCD tool refurbishment and manufacture. With its double-ended wheel spindle, it has the dual capability to erode PCD and grind carbide. This is ideal for customers looking to move into PCD by having a machine that is equally suitable for carbide or PCD tool production. This dual process machine reduces the financial risk associated with moving into new markets.

ANCA has over 30 years of tool grinding experience and is known in the industry for its tool design software and versatility. The EDGe has capitalised on this experience, offering manufacturers of PCD tools a high level of flexibility and productivity. The user interface is easy for inputting tool geometry and requires no time consuming programming ensuring tools are easy and quick to design and manufacture.

Precorp partners with suppliers willing to push technology

Precorp Project Engineer Duncan Wellesley with the ANCA EDGe erosion & tool grinding machine

The creation and development of the EDGe machine has involved a number of key partnerships. One of these is ANCA’s industry development partner Precorp. Precorp is a leading manufacturer of PCD cutting tools and a key supplier to companies such as Boeing in their production of the 787 (Dreamliner) aircraft. Precorp’s experience in PCD tool development provided the ideal beta test site for the EDGe machine to ensure it would meet the demands of industry and perform in a production environment.

Precorp President Richard Garrick stated that the ANCA EDGe machine had been beneficial in many aspects towards Precorp’s business.“A part of Precorp’s strategy is to constantly push existing manufacturing technology to achieve a technical advantage and differentiation in the market place,” he said.

“Key to this is partnering with machine suppliers that are willing to push technology and think ‘outside the box’. ANCA has always represented themselves to us as one of these suppliers. Our work together on ANCA’s new EDGe has moved EDG technology forward with regard to the manufacturing of PCD drills. “The ANCA EDGe machine facilitates the reconditioning of PCD drills which will, in turn, allow PCD drills and tools to be more widely used. The EDGe machine will allow the application and reconditioning of PCD tools in applications where traditionally it has been cost prohibitive. ANCA committed the necessary resources in the development of this project in order to ensure its success. Going forward we will continue to grow our relationship with ANCA and other suppliers that continue to deliver a technical advantage for our manufacturing processes.”

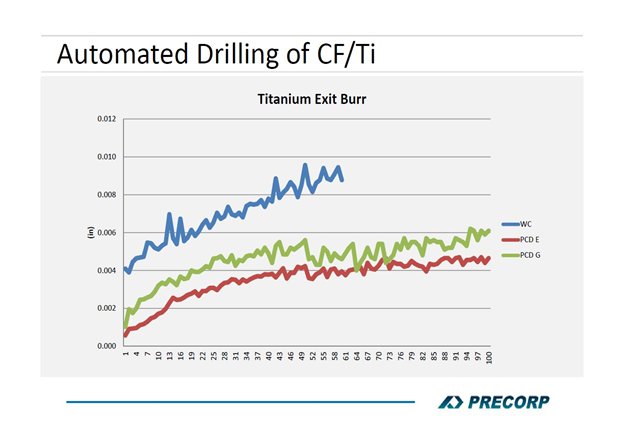

Exit burr results during Precorp drill comparison tests (drill manufacture via erosion versus ground)

WC = carbide, PCD E = PCD Eroded, PCD G =PCD Ground

The partnership with Precorp has allowed ANCA to measure and benchmark the performance of the tools being manufactured on the EDGe machine. Testing of tools eroded on the EDGe machine resulted in better figures for cutting force, exit burrs and drill life.

Comparative testing between a ground drill and an EDGe eroded drill has proven the ANCA machine produces a higher performance cutting tool. “The tools eroded on the EDGe are producing drills with a keener cutting edge than what we have seen on a ground drill,” says Garrick. “The holes drilled with these tools are producing less exit burrs and delamination which is highly desirable when using them on composite materials stacks, for example, CFRP, aluminium and titanium.”

RMIT provided data analysis for the EDGe development

Another key partner in the EDGe development was the Royal Melbourne Institute of Technology (RMIT – Australian university), who assisted the project through their PhD program with research and data analysis. Their intellectual expertise, combined with ANCA’s Engineering group, were able to develop a product that uses the latest available technology.

ANCA’s proprietary EDGe-Spark generator monitors and controls the energy level of every spark and adaptively adjusts the gap distance for optimum surface finish, material removal and cycle time. This provides exceptional operator feedback in real time statistical information on the erosion process.

The EDGe Spark automatically adapts each spark for the resistivity of the substrate, whether it is tungsten carbide, diamond or cobalt binder.

The EDGe is a versatile machine that is suited to a wide variety of industry tools and applications. Incorporating over 30 years of machine tool design in the tool manufacturing market, ANCA is excited about the launch of the new EDGe machine and believes that it will provide customers with a new level of capability for the production of PCD tools.

-nov-13.jpg)

Tools eroded on the EDGe machine meet more stringent quality figures

Download the EDGe brochure

2 November 2013