E-Sharp News

May 2022

Clorindo Mattei started Clortech in 1987, after quitting another specialty toolmaking enterprise in Montreal North, Canada.

The company has grown to about 20 employees, but maintains founder and president Clorindo’s enthusiasm for detail, his work ethic, and his pride in what’s created on the shop floor. Among the 20 are Clorindo’s wife Carmela, and children Emila, Mena Mattei, and Patrick Mattei.

“Everybody comes in and gives 110 per cent. Partly it’s about the fact that my dad came as an immigrant to this country with nothing but the clothes on his back,” explains Patrick, Clortech’s vice-president of production.

“He worked his butt off, and as an immigrant in Canada, you had to prove yourself twice as hard as a local to be able to get your foot in the door. And a lot of the spirit behind that is part of the product.”

The family business has remained at the 15,000 square foot site on Rue de Castille since 2003 but has happily moved with the times.

In the 80s and 90s, business was 100 per cent aerospace customers. The decade after – with 9/11 and the GFC – showed how temperamental that sector could be, and prompted diversification beyond it.

While Clortech was in its 100 per cent aerospace era, Patrick wasn’t sure he wanted to be in the precision toolmaking game. He’d been accepted into an architecture degree, and while he’d worked part-time at the family factory since age 14, he explains that “my dad only had conventional machines. Not that I was not interested in the conventional machines. There was just no appeal for me.”

After some reflection, Patrick decided “it would be wasteful not to seize an opportunity like this” and went into mechanical engineering at Concordia University while working part-time at Clortech. The same year, Clorindo saw the potential for the business to modernize with a second generation, and invested in Clortech’s first CNC machine, an ANCA TG7.

“By the time I finished university, we were up to three CNC machines: one grinder, one milling, one lathe,” he recalls.

“Then once I graduated, things just were on the up and up and we just kept on adding machines. We weren’t really big spenders, and were very cautious and frugal. We’d buy one machine at a time, and slowly but surely, they added up.”

Today the company has two each of ANCA’s TG7 Plus, TX7 and TX7 Linear machines, as well as CNC lathes, mills, and an assortment of manual machining equipment in its workshop.

The customer base has also expanded, with maintenance and repair gear going out to the Canadian Armed Forces, and drills to railway sleeper installers, as well as tools for traditional clients like Pratt & Whitney.

Branching out has been a buffer in the COVID-19 era, which hasn’t been gentle on airline operators and others.

“The slowdown in aerospace was absorbed by the increase in commodities being shipped by rail,” says Patrick.

Aviation however remains important to Clortech. Part of its offerings – besides MRO kits, tool production, and contract tool development – is AOG 911, a quick response tool production and repair service.

“Aerospace is not strictly about complex tools, but often the urgency of the tools. A lot of the time we get requests for aircraft that are on ground, be it in Montreal or around the world,” says Patrick.

“These aircrafts have to fly, so they'll call us and request a tool to be made on a turnaround that's within the day, within a couple of hours or within the next day. And it may be a simple tool or maybe a complex tool, and we've got to turn around and make it as quickly as possible and make it right the first time.”

Asked about plans to invest in lights-out and other high-level automation solutions, Patrick says that scaling the company up is not the priority, rather it’s about doing the finest work possible and being competitive at small volumes.

“The software that ANCA has allows us to be able to program the machine in a time-efficient fashion when producing low-volume parts. It is so conversational, so user-friendly, that it's simply a plug and play,” he explains.

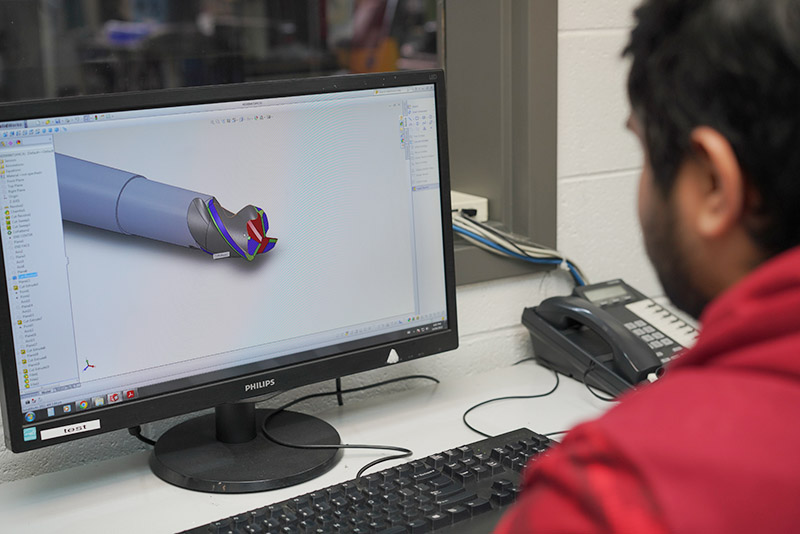

“When we had our first machine, they had designed it with a simulator that allowed us to see the tool in a 2D state. It was great at the time, and state of the art. But now that we see the software that allows us to do 3D renderings of a tool before we actually take that program and transfer it to a machine, it allows us to really be able to grind a part virtually, off-line, saving us a bundle of time on the machine.

“When you're doing the volumes like we are, we are not making 4 million parts or even a thousand parts or even 200 parts. So when you're making three endmills or two drills, you’ve got to be doing that quickly. Software allows us to do so, and that's what attracted us to the product in the beginning.”

Xiaoyu Wang, TX Platform Product Manager at ANCA says: “ANCA is the first tool and cutter grinder manufacturer to apply advanced computer-aided design into the cutting tool industry. The analytical engine of the CIMulator3D simulates the material removal process by precisely moving the models of the grinding wheel to cut through the blank. It enables the tool designers to analyze the tool geometry and operators to optimize the grinding process.”

“The newer development such as MRR graph further enhanced the capability of CIMulator3D; it has become an analytical tool offers more insights of the grinding process. I think tech-driven customers like Clortech will realise its full potential,” she concluded.

Patrick says Clortech could soon invest in another ANCA CNC machine, but is waiting to see how the economy is impacted by the Russian invasion of Ukraine.

The main thing is to continue running a family business, based on pride and passion more so than chasing growth for the sake of it. Patrick points out that he and his siblings are all university-educated, and some have quit jobs at multinationals to return to the family business on reduced salaries.

“It’s the fact that we can make a product, give 110 per cent, and make it better than anybody else. And there's a lot to say about the pride behind the name and the product we sell versus just the money we make,” he offers.

“No one says of Ferrari: ‘How much money did they make this year?’ They say, ‘look at this car, it’s a beauty.’ And we actually get a lot of our drive from customers calling us and saying that they love the performance of the tools. Pretty much it’s the pride behind it that drives us.”

7 April 2022