E-Sharp News

July 2017

Our customers have achieved great results from ANCA’s LaserPlus and after listening to feedback on how to make it even better we can now offer the market a range of significant enhancements on the product. The new features include:

• support for woodworking compression routers;

• ability to grind corner radius and ballnose on pre-ground OD Endmills;

• trimmed profile;

• X distance measurement;

• ability to measure the maximum OD and compensate;

• measurement report for ballnose and corner radius tools;

• multiple measurement points for cylindrical grinding;

• support for shear tools with insert width on shear plane.

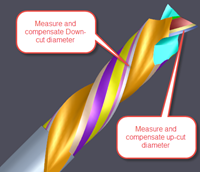

Support for woodworking compression routers

It’s a challenge to maintain a constant diameter between up and down cut sections on compression router cutters mainly due to significantly different axes positions during fluting. LaserPlus now supports measurement and compensation of both up and down cut diameters or individual sections. This enhancement will be a boost in manufacturing of compression router cutters where consistency will be maintained between the cutting diameters during batch grinding.

Ability to grind corner radius and ballnose on pre-ground OD Endmills

Many customers grind large batches of tools with the overall diameter (OD) finished ground, but do not grind the end face. This approach enables tool manufacturers to keep large amounts of OD finished tools in stock waiting for end face grinding (i.e. ballnose or corner radius) in smaller batches to meet their customer’s specific requirements. This strategy shortens lead times and offers improved service to the end user of the tools. LaserPlus now has the capability to measure pre-ground OD and match the end face grinding for corner radius and ballnose tools.

Trimmed profile

This feature allows users the possibility to trim the profile and measure the trimmed elements which requires high accuracy. This also can be used where extensions are created to grind certain profiles but measurement is only required for the correct profile form. The operator can choose the element in the profile they wish to measure (like iView) with the possibility to select the start and end points to be measured on the entire geometry.

X distance measurement

X distance measurement is now available and logged in the grind log during batch grinding. It is displayed on the screen when Dig Now is used. The distance is normally used to compensate the X position of a tool profile manually. There is an option to stop the batch production if the measured x-distance is outside tolerance.

Look out for our next E-news where we will update you on the remaining new features on second generation Laser Plus.