E-Sharp News

March 2022

A guest article by Steven Lowery (Executive VP, oelheld) and Markus Munde (Technical Support Engineer, oelheld)

With continued objectives to improve your grinding operations, every aspect of the process needs to be evaluated. Selecting the right machine tool, grinding wheels, tool holders, tool paths, and of course your grinding oils. Unfortunately, many see the fluids as an unnecessary evil to the process, failing to realize that selecting the right grinding fluid can lead to significant improvements in cycle time, surface quality, finishes, secondary operations, such as tool coatings.

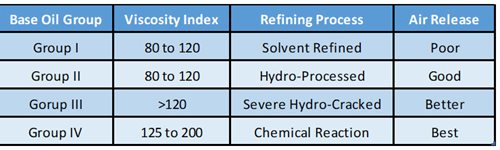

As you begin your journey to evaluate grinding oils, some basic background information should be considered. The category of the base oils and additive package is key to your success. There are 4 categories of base oils, I, II, III, IV that are used in metalworking fluids. To achieve better performance, consider products made with Group III base oils. These oils are severely hydrotreated to remove impurities, improve viscosity index, and stability. Being derived from mineral oil, they are not synthetic. Some manufactures and producers may use the term “synthetized” to cause confusion with the end user. Synthetic they are not. Group III base oils also contains the gas to liquid, or GTL base oils. The GTL base oils have better characteristics than their sister products in Group III, but below those in Group IV. These oils are derived from converting natural gas into oil. In many instances, there is measurable performance benefits by moving to GTL based grinding oils.

As you begin your journey to evaluate grinding oils, some basic background information should be considered. The category of the base oils and additive package is key to your success. There are 4 categories of base oils, I, II, III, IV that are used in metalworking fluids. To achieve better performance, consider products made with Group III base oils. These oils are severely hydrotreated to remove impurities, improve viscosity index, and stability. Being derived from mineral oil, they are not synthetic. Some manufactures and producers may use the term “synthetized” to cause confusion with the end user. Synthetic they are not. Group III base oils also contains the gas to liquid, or GTL base oils. The GTL base oils have better characteristics than their sister products in Group III, but below those in Group IV. These oils are derived from converting natural gas into oil. In many instances, there is measurable performance benefits by moving to GTL based grinding oils.

If you really want to ramp your performance, look to Group IV, Pure Synthetic base stock products. Group IV base oils are composed of polyalphaolefins (PAO). They have high viscosity indexes (the measure of a fluid’s change in viscosity relative to temperature change). These base oils are not extracted from crude oil, but made from small, uniform molecules, allowing for very predictable properties and end results. Grinding oils produced with PAO’s will offer you the highest performance, process stability, longevity. While grinding oils produced with PAO, will be at the top tier in pricing, the benefits and results far outweighs the marginal increase in purchase price.

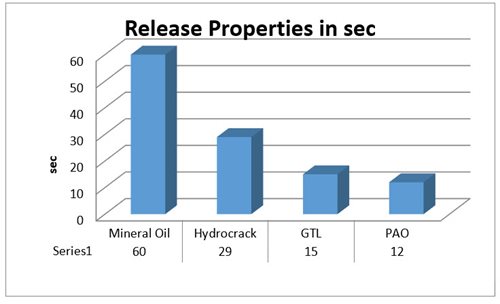

One key attribute is the foam generation, or air release properties. Air is a poor medium for cooling and lubricating. With lesser grade base oils, there is more foam and air entrapment it the oil. This can lead to poor lubrication, poor cooling, surface defects, and poor filtration. Select a grinding oil that has the proper air release properties for your operation.

Not only does the base oil selection play an important part, the quality and abundance of the additive package within the grinding oil is key. There is a wide ranging selection of additives available to grinding oil producers, as well as the base oil quality. Think of the “good, better, best” analogy. By cutting costs, using a good quality base oil with the best additive package, does not make an outstanding product. But when you combine the best quality base oil, with the best quality, state of the art additive packages, now you have innovative fluid technology. Combining the expert research and development of an industry leading formulator, along with top additive producers, the end result is a grinding oil that will not only meet, but exceed your expectations.

If you want to know more about how innovative fluid technology works, and how your operations can benefit, reach out to us at

hutec-us@oelheld.com to begin the conversation. Our decades of grinding oil expertise, and collaborating with ANCA CNC Machines, can provide you with state of the art solutions to take your operations to their highest level.

10 March 2022