E-Sharp News

August 2022

The market for production of indexable inserts is one of significant opportunity to tool manufacturers. Market data indicates not only is the value of the inserts market larger than solid cutting tools, but its annual rate of growth also is higher.

These facts provide strong incentive to be active in this market, but insert manufactures must tackle unique and widely varied challenges for competitive insert production. The enormous diversity in insert geometry demands a partner who can deliver grinding machines with solutions in automation, work holding and programming software that can be adapted to the unique features and cutting edge geometries seen in the inserts market.

AB Tool Inc. (California, USA) has been the first of a number of insert manufacturers that worked closely with ANCA Engineers to deliver solutions to these challenges. By systematically addressing the key elements of insert geometry and the required tooling and automation, ANCA has developed a suite of solutions, based around its

MX grinding machine platform that are adaptable to a wide variety of insert designs.

Indexable inserts account for a significant portion of the broader insert market and their uses are wide and varied. Whether for cutting, turning, parting, scarfing, hobbing, profiling or threading – insert applications and their designs are seemingly limitless. Both standard ISO and special form inserts can be ground with ANCA solutions, but given ANCA’s track record of developing highly flexible and adaptable application software and automation, ANCA customers tend to be focused on the ‘special insert’ application where geometries and cutting features are more complex, but the financial rewards are greater.

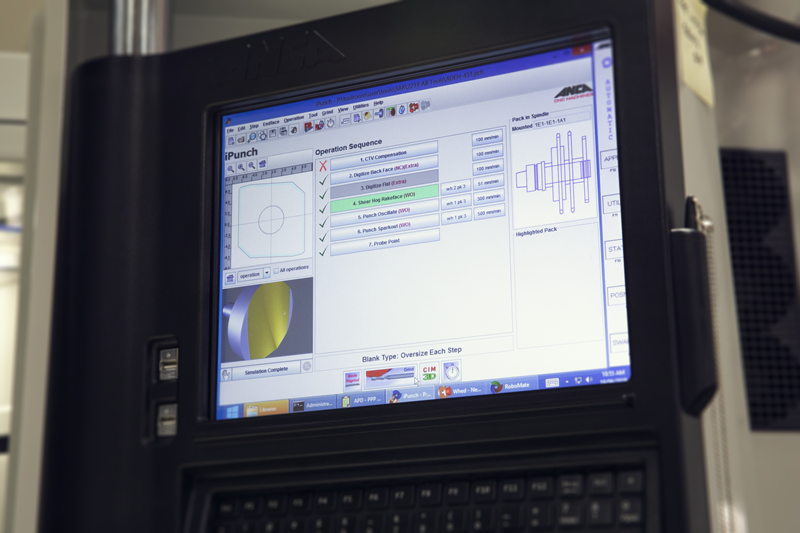

ANCA’s latest software developments include digitizing routines to accurately locate insert position and index or datum features. Tool programming software includes a variety of grinding operations that allows customers to produce both ‘on edge’ (or tangential cutting) inserts as well as ‘lay down’ (or axial cutting) inserts.

Using ANCA’s CIM3D, the complete part grinding process in the machine can be visualised and the finished insert checked and reviewed before true grinding starts.

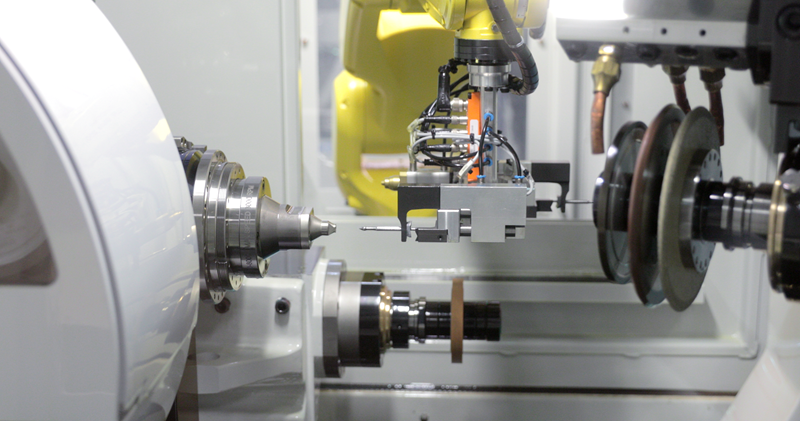

Equally important is the tooling and automation solutions that can be readily adapted to account for the various insert geometries presented by different applications. On the MX machine platform, ANCA has developed modular solutions that can be customised and adapted to unique customer needs.

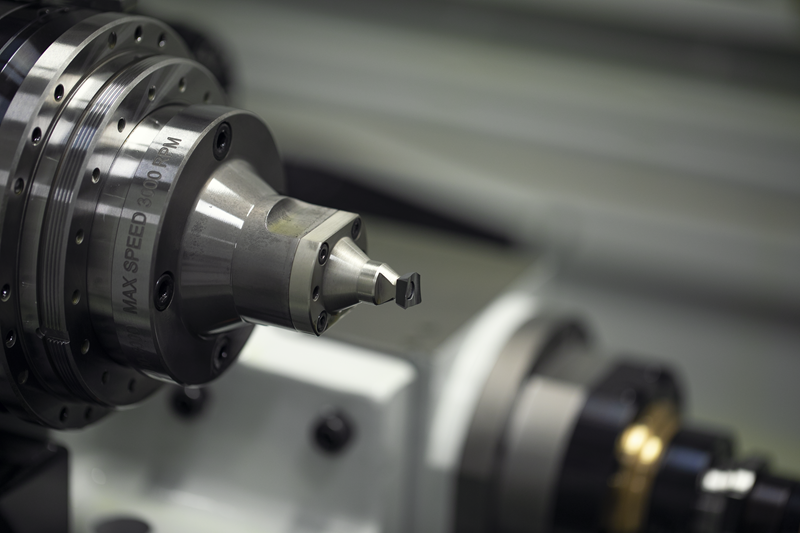

Insert work holding is based around the proven ‘pin clamp to anvil’ system.

This system is offered with custom tooling to accommodate different insert hole diameters and geometry as well as varying thickness. Variable pin clamp force is also offered as an option to account for different grinding forces generated when grinding different size inserts.

Automation for unattended production is also designed with flexibility and efficiency in mind.

Inserts can be presented in industry standard plastic pallets, allowing one pallet to be used for a variety of insert shapes and sizes. The robot tooling used to pick up and load the insert is also designed to customer requirements and will handle varying insert size, thickness and shapes.

These modular and adaptable solutions for special insert production have been the result of close co-operation between customers and ANCA design and development engineers. Such a collaborative approach has ensured that customers specific needs have been answered and the foundations are laid for solutions for other customers looking to gain the edge in the lucrative market of special inserts.

18 July 2022