Auto wheel pack qualification is available on the FX, MX and TX range of machines. It’s a substitute for qualification bars and off-machine wheel setters. It uses a Renishaw probe to qualify the wheel pack inside the machine with the support of wheel probe software.

Using iGrind, the operator can choose what aspects of the wheel pack to qualify before triggering the qualification cycle. Before the wheels are digitised, the probe itself is re-qualified using a qualification block attached to the spindle housing. Wheels need to be measured in the 6 o’clock position, to avoid collision with coolant pipes.

All machine platforms have an indexable wheel spindle as default, meaning the spindle can be set in axis mode (Q-axis) for commanded position rotation. This allows the operator to specify in iGrind how many points around the wheel are to be digitised for the wheel qualification.

Types of wheels able to be qualified include 1V1, 1A1, 11V9, 2CH3R, Double Radius, 1F1, Profile, Radius Wheel and 11M2.

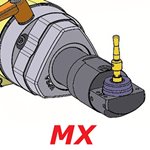

The systems for the FX, MX and TX7 series machines are different as per the images below.