News

Product News

Do you have a need for increased spindle speeds? ANCA’s Spindle Speeder together with ToolRoom’s new pocket grinding feature efficiently enables PCD pocket grinding applications.

ANCA now offers a spindle speed increaser for the FX machine platforms, previously only available on MX and TX platforms.

The Spindle Speed increaser on FX allows grinding of small tools with speeds of up to 50, 000 RPM

Increase speed for efficiencies with very small diameter wheels

The spindle speeder can turbo charge the spindle up to 50,000 revolutions per minute (RPM) to easily grind Polycrystalline Diamond (PCD) pockets. Together with the new ToolRoom RN34 enhanced Pocket Grinding feature, the intricate geometries and increased grinding speeds for PCD pockets combine in one set-up.

PCD tools are used in the woodworking and aerospace industries and typically grind composite and non-ferrous materials.

With grinding wheels becoming smaller, it is important to achieve the right surface speed of the grinding wheel as this is a critical factor of efficient grinding. The increasing demand for smaller grinding wheels requires more revolutions of the spindle to keep the grinding speed at the desired level.

Typical carbide tool grinding operations like fluting or OD relief use 2,500 RPM up to 4,000 RPM depending on the wheel diameter. However, special grinding operations like PCD pocket grinding requires the use of very small diameter wheels. The wheel diameters in this application can be as small as 10mm. With grinding wheels that small the spindle speed must be between 30,000 and 40,000 RPM to maintain an efficient grinding process.

The speed increaser’s gear mechanism increases the RPM by a factor of seven up to a maximum speed of 50,000 RPM. It requires no special changes to any ANCA machines as it adapts directly into the main spindle HSK system and can be changed as easily as a regular wheel pack.

The spindle speed accessory has now been extended to the entry-level FX platform and full FX machine range to provide even greater flexibility and productivity for a range of manufacturing needs.

Pocket grinding cycle time estimation on FX machines

In pocket grinding operations the spindle power doesn’t have any significant impact on productivity, however it can still take up significant machine time. Therefore, it can be a smart business proposition to use an economical machine like the FX3 with one grinding spindle to perform pocket grinding on pre-fluted tools.

Alternatively, the FX5 with two-wheel packs can perform grinding of the complete tool in one set up offering unattended production with automated tool change.

In any case the FX platform is highly suitable for pocket grinding and can help companies to free up valuable production capacity from other machines.

Most common and simple cases:

• 3 Flute step tool with 15-degree helix

• Two pockets on each flute

• Major diameter 16mm

• Minor diameter 10mm

• Step length of 18mm

• 45 degrees’ step angle

Extreme cases with larger number of pockets but shorter pocket length:

• 4 Flute 15-degree helical tool

• 6 pockets on each flute but staggered.

• The entire cutting edge had PCD coverage

• Diameter 10mm

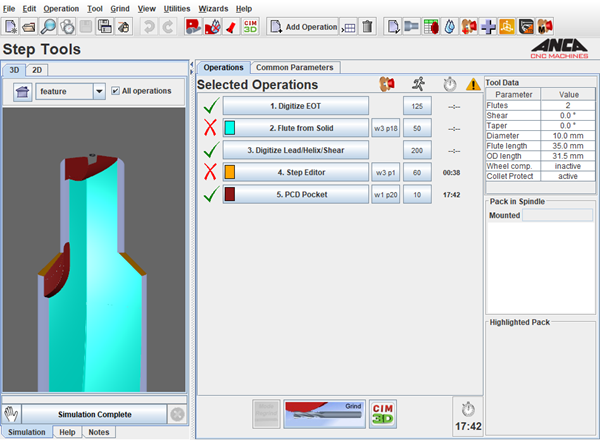

Define PCD pocket geometries with ToolRoom RN34 features

Examples of 10mm shear tool on FX platforms. The above image shows the complete tool with two

wheel-packs on an FX5 and the below image is an FX3 with just pocket grinding on a pre-fluted tool.

ANCA’s speed increaser accessory and specialist pocket grinding software provide the ideal solution for grinding small insert pockets efficiently. These features combined offer further opportunities for getting maximum value from your machine tool investment.

PCD pocket software allows the user to quickly and easily define PCD pocket geometry. This applies to all PCD Profile routers, drill or counter sink tools.

29 June 2020