E-Sharp News

August 2012

-aug-12.jpg)

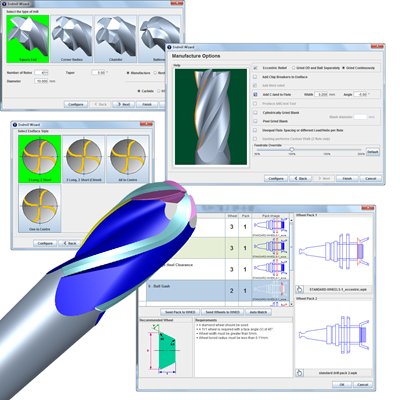

New Endmill Wizard

In ToolRoom 2012 there is a completely new and comprehensive Endmill Wizard within iGrind for ballnose, corner radius, square and chamfered end mills.

- Automatically and easily generate production ready tools directly on the machine

- Includes many options to customise the tool geometry

- Automatic wheel selection and recommendation

- Simplifies endmill programming and reduces operator training time

- Completely customisable. Define your own wizard behaviour to cater for your tools and production methods

- Create multiple customisation sets to suit different product ranges

Along with the new integrated 3D graphics in iGrind, the End Mill Wizard will greatly simplify tool programming and reduce set-up times.

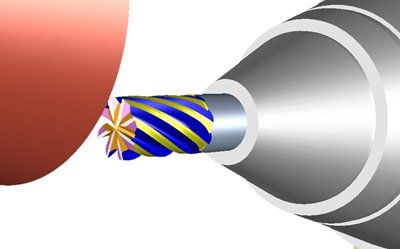

Auto Wheel Orientation – End Face

Wheel orientation and clearance is automatically calculated for End Face Finishing and Tertiary operations.

- Calculates required values per flute to avoid interference

- Ability added to manually specify values for each flute

- Simplifies programming of end mills with many flutes

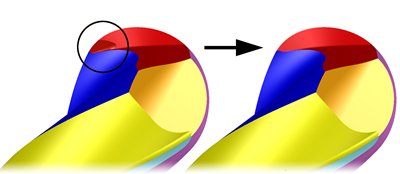

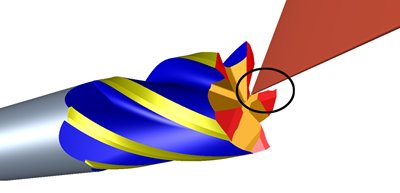

Ball Gash Undercutting Detection

Automatic detection of potential undercutting when grinding the ball gash which may result in a visible grind mark.

- iGrind will warn and recommend values to rectify the issue

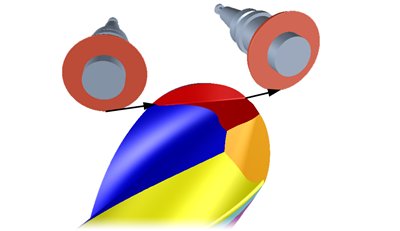

Ball Gash Extensions

5-axis grind path extensions for the Ball Gash operation.

- Extensions can be automatically or manually specified

- Improves surface finish by eliminating potential approach or retract grind marks

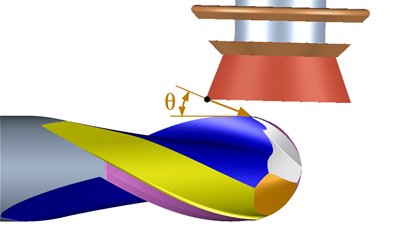

Ballnose – Angular Path Extension

Option added to the OD and Ball Finish cycle to allow an angular 5-axis approach move into the ball.

- Can improve surface finish by approaching the ball at a small angle

- It also eliminates the possibility of introducing a step on the OD-Ball transition point when using a two-path method.

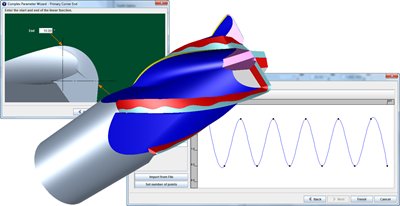

Complex Variables for Corner Radius

Complex variables available for Corner Radius Primary and Secondary relief as well as land width.

- Ability to vary geometry along these features

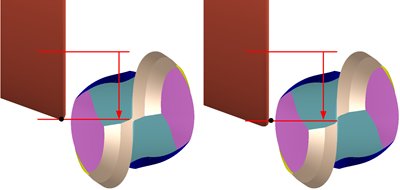

Corner Radius Gashing

Option added to Corner Radius Gashing operation to control the depth with respect to either the wheel periphery or toroid center.

Endface and Point Gashing Clearance

Ability to specify a wheel clearance angle in Endface and Point Gashing in order to improve surface finish.

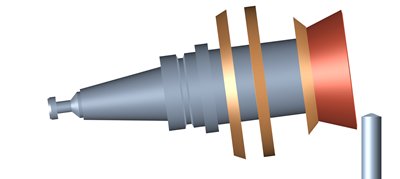

Eccentric Cup Wheel Qualification

A new method has been added to the Wheel Editor to easily and accurately qualify an eccentric cup wheel (11M2) using a qualification bar.

Other new features in ToolRoom 2012 specific to Endmills

- Wheel side selection (front or back) is now available for the Endface and Point Gash operations

- Grind-Digitise-Grind compensation for Laser OD SPC

- Arc blanks automatically used in Cim3D for Ballnose tools

- Compensation for shear Ballnose tools

12 August 2012