E-Sharp News

May 2022

ANCA CNC grinders, long recognized for their flexibility and industry leading software in the tool grinding industry, have had their capabilities expanded with the development of a new software package designed specifically for production of internal boring bars or internal turning tools.

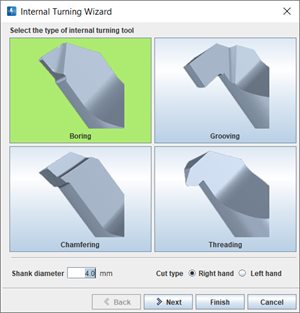

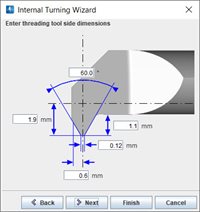

The Internal Turning Tool Wizard will greatly simplify the process of program preparation for boring bars. The Wizard includes a step by step programming interface with parameter input and help menus that are specifically relevant to boring bar geometry. Also, a selection of new operations means the unique features required on boring bars can now be easily programmed. Making tool program creation simpler gives you greater capacity to quickly create new tool geometries specific to your customers needs.

New to boring bars?

New to boring bars?

Boring bars are used on turning machines, creating the internal geometry of a circular hole. For a straight hole creation, boring bars have advantages over conventional drills, producing more accurate hole geometry, better surface finish and can make the hole to any size you choose, rather than being fixed to the drill diameter.

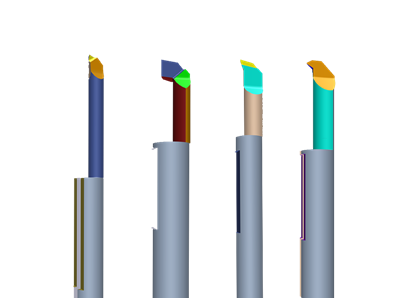

Beyond straight holes, boring bars come in many shapes and sizes, so they can be applied to create other features inside a turned hole, such as profiles, grooves, threads and chamfers.

Whilst large diameter boring operations can be done with an insert held in a tool holder, solid carbide boring bars are required for smaller holes and features. This is the application addressed with ANCA’s new Internal Turning Tool Wizard software.

Boring solutions for the boring market

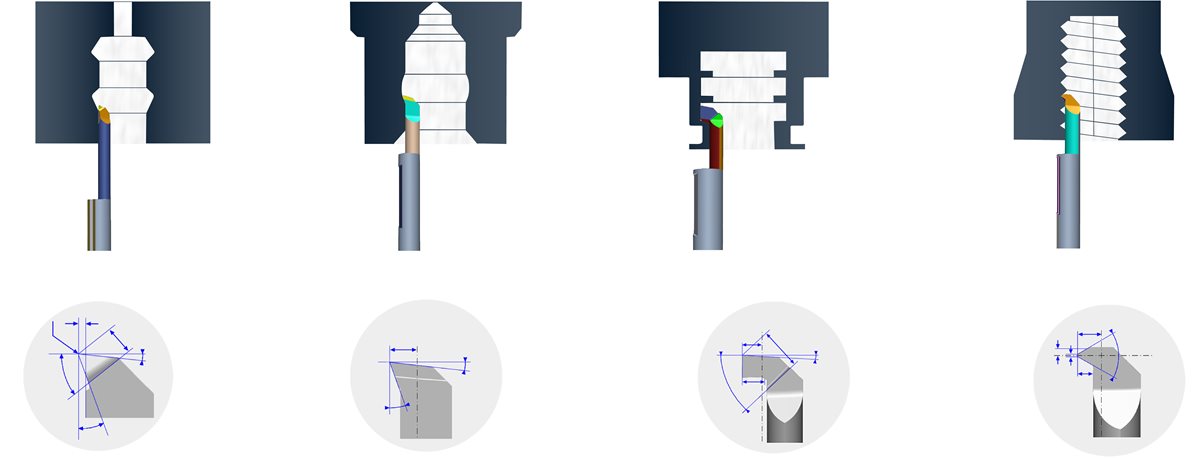

ANCA software is long established with grinding of rotary cutting tools, however to make solid carbide boring bars, a whole suite of new grinding operations has been developed with extensive input from customers experienced in making these tools.

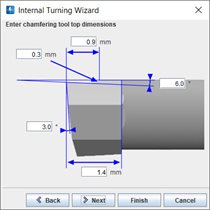

The Internal Turning Tool Wizard allows the Programmer to select the type of tool – boring, grooving, threading or chamfer. This sets up the basic cutting edge geometry that is parametrically input via a graphic menu. Other features such as necking, datum grinding and coolant grooves are additionally added in the wizard.

Automated production

Automated production

Unattended production is of course supported with ANCA automation solutions. ANCA offers robot automation across its entire tool grinding machine range. FX can be offered with a single pallet which would easily support overnight tool production. MX and TX has additional capacity in their loader system with 4 pallets that will keep your machine producing tools over multiple shifts. ANCA machines are offered with additional options to ensure unattended production remains consistent and accurate. This includes automatic white stick for wheel conditioning, in process wheel dressers and CTV (Compensation for Thermal Variation) system that compensates for the impacts of ambient temperature variation on the machine.

ANCA also offers processes that will grind shank features, for example index and witness notches, in the same setup as the cutting edge grinding. This can eliminate separate operations and setup that might otherwise be necessary in an additional machine process.

Once again, ANCA brings to the market solutions designed to meet the particular needs of tool producers, this time in the boring bar market. User friendly software makes programming these complex tools simple and fast, while clever automation eliminates up stream processes and delivers many hours of unattended production. A sure recipe for success in this niche market.

10 March 2022