News

Product News

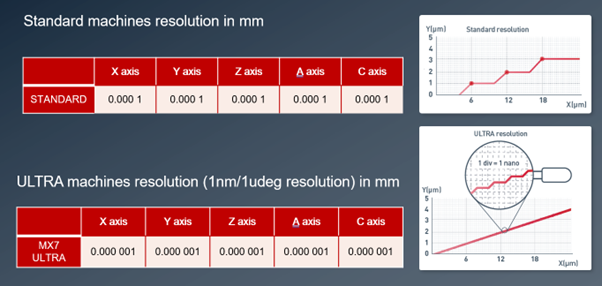

ANCA, a leading provider of CNC grinding machines, has introduced a groundbreaking nanometre control system that sets new standards in precision machining. This cutting-edge technology enables silky smooth movement of all linear and rotary axes, resulting in exceptional surface finishes on cutting tools. The nanometre control system offers unmatched accuracy, flexibility, and performance, empowering manufacturers to produce a premium range of cutting tools with the utmost precision. By leveraging ANCA's expertise and deep industry knowledge, the ULTRA range of machines equipped with this revolutionary control system opens up new possibilities for the grinding industry.

Unparalleled Accuracy and Flexibility:

The nanometre control system implemented in ANCA's ULTRA machines represents a significant advancement in precision machining. The system incorporates ANCA's best-in-class technology and leverages the company's vertical integration, enabling robust and scalable improvements throughout the machine. This holistic approach ensures optimal design and functionality, resulting in an unrivaled level of accuracy, performance, and tool life.

Silky Smooth Motion and Servo Control Algorithm:

Smooth and precise motion of machine axes is crucial for achieving high-quality surface finishes on cutting tools. ANCA's nanometre control system utilises a state-of-the-art servo control algorithm, allowing for silky smooth axis movement. This unique algorithm, combined with nanometre-level measurement capabilities, ensures ultra-fast response to internal and external disturbances. By effectively mitigating irregularities originating from linear rails, bearings, or friction, ANCA's control system guarantees outstanding tracking performance. Furthermore, it accomplishes this without the need for complex and expensive mechanical systems, thereby streamlining the manufacturing process.

Elimination of Reversal Errors and Secondary Operations:

One of the remarkable features of ANCA's nanometre control system is its ability to reduce reversal errors to the nanometre scale when an axis changes direction during grinding. This precise control eliminates any reversal marks that could potentially affect the tool's quality. Consequently, the need for secondary operations such as finishing or sparkout is significantly reduced, resulting in improved cycle times and increased productivity for the production of high-quality cutting tools.

Enhanced Surface Finish and Productivity:

With ANCA's nanometre control system, manufacturers can achieve exceptional surface finishes on cutting tools, surpassing previous industry standards. The system's ability to eliminate reversal marks, combined with its smooth and precise motion control, ensures superior surface quality. The reduction in secondary operations not only saves time and resources but also enhances productivity. Manufacturers can now deliver premium cutting tools with shorter lead times, while maintaining exceptional quality.

ANCA's nanometre control system represents a groundbreaking development in precision machining and sets a new benchmark for the industry. By incorporating advanced servo control algorithms and nanometre-level measurement capabilities, this cutting-edge technology enables silky smooth movement of machine axes, resulting in exceptional surface finishes on cutting tools. The system's ability to eliminate reversal errors and reduce the need for secondary operations enhances productivity and overall efficiency. ANCA's ULTRA range of machines equipped with the nanometre control system empowers manufacturers to achieve new levels of accuracy, flexibility, and quality in the production of cutting tools, solidifying ANCA's position as an industry leader in CNC grinding technology.

10 July 2023