E-Sharp News

August 2012

The new MX5 is the dream machine of affordable tool grinders, especially for volume endmill production. Right in the middle of our range, between the entry level FastGrind and the larger TX series, the MX5 replaces the hugely popular RX7 (there are over 1,000 RX7 machines in the field).

As it is an MX series machine, which is a more premium model that the RX7, it is even more accurate and stable than the RX7. However, although the MX Series is usually more expensive, the MX5 has been designed specifically to focus on stability and accuracy, whilst offering a more economical option by altering a couple of features such as the number of wheel packs.

The MX5 has a wide productive range of tools that makes it suitable for everything from micro-tools up to tools with shank sizes of 16mm (5/8”).

Productive Range - Tool (shank) Diameter

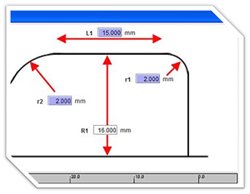

Production endmill grinding is tough on tolerances. Because the OD of the tool is ground completely on the machine, any accuracy or instability problems in the machine translate directly into tool inaccuracy. This is particularly apparent on ballnose and corner radius endmills where tolerances are often as tight as ±3-5μ. Tolerances continue to fall, so machine accuracy and stability are now the #1 requirements for many endmill production jobs. Which is why we decided to replace the RX7 with a machine based on the proven bi-symmetrical gantry design of the MX7.

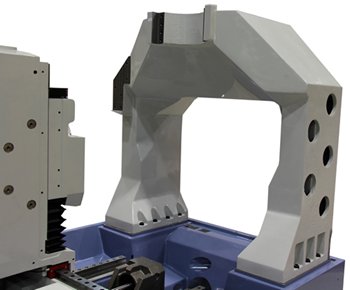

Bi-Symmetrical Gantry for Enhanced Accuracy and Stability

Our customers have known for a while that the bi-symmetrical gantry design of the ANCA MX Series and TX Series machines offer the best possible accuracy, stability and rigidity.

Our challenge was to bring this design to a wider audience. Volume endmill producers work to very tight profit margins, and although impressed by the MX7, they often found it too expensive for their budget.

The new MX5 now has all the rigidity, stability and accuracy characteristics of the proven MX7, all at a lower price.

We achieve this by using a lower powered spindle (26kW-MX5 vs. 38kW-MX7) and fewer wheel packs (2-MX5 vs. 6-MX7). This is perfect for many customers' requirements and is still an ideal specification for the grinding of the majority of endmills up to 16mm (5/8”).

ANCA pioneered the bi-symmetrical gantry with the TX7 and refined it for the MX series, providing the MX with the best thermal and vibration stability properties ever seen in an ANCA tool grinder.

Evenly straddling the tool centre line, the spindle gantry minimises the effects of thermal growth.

The design also allows the grinding wheel to remain very close to the C axis pivot point. This configuration produces the highest levels of profile accuracy for tools requiring substantial 5 axis movements, such as corner radius endmills.

The MX5 also includes an orientation synchronised wheel changer to ensure that every wheel pack is loaded perfectly and repeatably into the accuracy “sweet spot” at the center of the bi-symmetrical gantry.

High Accuracy Tooling Option

The optional Overhead Top Clamp (OTC) fully constrains the tool blank to perfectly aligned rotation about the machine’s X-axis direction. It ensures an amazingly low run-out and a highly repeatable set-up. Both when you are loading blanks by hand, or by auto-loader.

Hans-Werner Nikolaus of H.W. Nikolaus Grinding Tech in Kirkel, Germany summed up the heritage of the ANCA MX series for endmill production:

“We bought our first ANCA in 1992 for conical ballnose endmills. We now have 8 ANCAs including a new MX7. The MX7 is a very good product. Price, precision, competitiveness and the wheel exchanger – I wish I had one 3 years ago!”

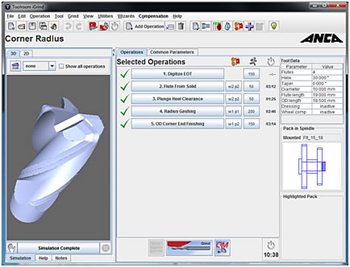

ANCA’s Brand New Software for Grinding Endmills

Machine accuracy may be the #1 factor for endmill manufacturing, but it’s by no means the only thing to be considered when choosing your next machine. With batch sizes falling, how quick and easy the machine is to set-up and program becomes increasingly important. The MX5 excels in this area as well.

ANCA software has always been considered flexible and easy to use. And now, to coincide with the launch of the MX5, we take that ease of use to a new level with ToolRoom 2012.

This is our most significant software update in years. It includes a super easy to use new endmill wizard and intelligent, integrated 3D graphics simulation as standard.

Setting up a new batch of endmills has never been easier.

Superior Productivity with ANCA’s High Capacity, 'RoboMate' Universal Robot Loader

RoboMate is a high capacity and compact loader option available on the MX5 for production or resharpening. It’s a breeze to use, just enter how many of each tool to make, and RoboMate figures out the rest.

Does an Endmill Grinder Need to be Flexible?

Easy to use often means ‘restrictive software’. Not so with ANCA. Our software and machines have set the benchmark in flexibility for years.

The ANCA software lets you easily design and grind many different types of tools. It’s when you get those really difficult jobs that you will really be able to appreciate what you can do with ANCA software, and where other systems can fall short.

Even if you only grind endmills on your MX5, with ANCA’s flexibility you can get the edge on your competition by adding custom geometry to your tool designs. For example, adding chip breakers, complex land geometries or varying the gash profile in subtle ways.

“We have huge demand for high end, high quality tools. Lots of special tools with combined features (eg: endmill and reamer in one multi-functional tool). ANCA is known for the flexibility of the software.”

Jin Jianbing, Changzhou Kenda Tools, Changzhou, China

2 August 2012