As an industry #ANCATooloftheYear celebrates the knowledge and imagination of cutting tool craftsmen, creating tools with the perfect geometry, profile, and finish that shape and build our world everyday.

February 2020: KV Tooling took out the coveted first place in ANCA's industry first competition, ‘ANCA Tool of the Year’. The cutting tool industry has cultivated and refined their craft over the years to design beautiful tools, applying science to achieve a sub-micron surface finish and superior cutting performance.

Pat Boland, ANCA Co-founder said “All finalists were of a very high standard and demonstrated a deep understanding for tool geometry as well as taking full use of ANCA’s software to design unique and special cutting tools. We congratulate the winner KV Tooling, runner up Eshed Tools and Zakłady Mechaniczne Kazimieruk who we gave a special creativity award for daring Bat Man design.”

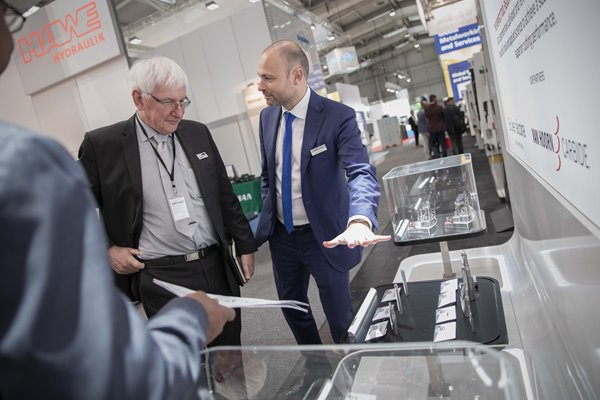

Pat Boland, ANCA's Co-Founder with Ralph Van Hoorn, owner at Van Hoorn Carbide

Brian Beland, President at KV Tooling Systems said on winning the award: “Competing with world class tool grinding shops from around the world with same grinding machines and winning - regardless of the size of the shop - is something we are particularly proud of.”

“Our entry was a very complex tool with many features incorporated into one tool. We designed the cutting tool to satisfy a customer’s problem, where our one tool replaced a machining requirement that previously required six tools. The customer was very happy with the production gains and for us to submit to ANCA Tool of The Year. We believe winning the competition makes our company more marketable and will give us great exposure and hopefully expand our customer base,” concluded Brian.

ANCA Tool Of The Year finalist tools displayed at EMO 2019

Eshed Tools entered the competition to share their special tool manufacturing skill set with ANCA users. Shmulik Arbel, Production Manager commented that they were proud of their expertise that means they can “produce special geometries that are difficult to achieve and save our clients expensive production time.”

Reflecting on coming runners up Shmulik continued, “Taking out this prize creates a great opportunity for global exposure through the Tool of the Year competition. For us ESHED tools as a small and growing tool manufacturer, world wide recognition is important and will help us expand beyond the local market.”

Zakłady Mechaniczne Kazimieruk on winning the ‘Most Creative Tool’ said: “We thought outside the box and were motivated to inspire the grinding community with our entry. During everyday work our team make a lot of customized tools so we wanted to make something fresh and unique – even to us. Furthermore, entering was a great test for our grinding skills. We relished the opportunity of seeing others craftmanship and the entries in the tool of the year competition demonstrated to us the range and type of cutting tools that are possible.”

The competition was based on the passion and the craft of tool making and celebrate our highly skilled tool grinding community. Watch the live annoucment of winners at EMO 2019: