E-Sharp News

October 2020

When grinding long slender tool blanks, best practice means supporting the blank at the end of the tool. Slender blanks need extra support to prevent “whipping” (deflection) at the end of the blank which can lead to tool breakage. This whipping effect is particularly common on smaller diameter blanks rotating at high RPM. Using extra support at the end of the blank ensures consistent parts and high quality on the finished tool. For companies producing long drill blanks, in many instances a Tailstock is the ideal solution.

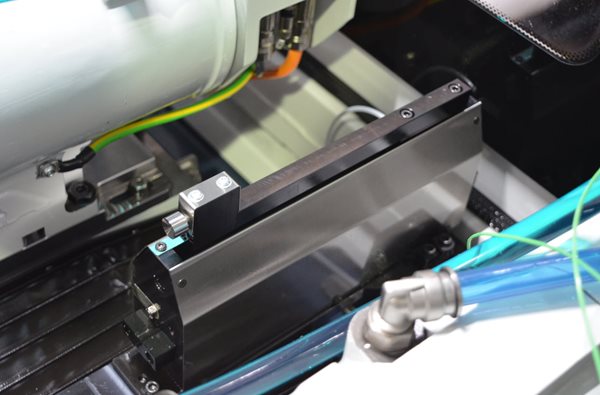

To solve the problem of supporting long slender blanks when pinch/peel grinding on the CPX Linear Blank preparation machine, ANCA has released the Tailstock assembly. Supporting the end of the blank when grinding prevents deflection so perfect parts are produced. The Tailstock assembly is pneumatically operated using live centres to support the blank. The Tailstock mounts in the base of the machine and consists of a live centre with an arm mounted on a pneumatically actuated carriage. The extendable arm moves forward and catches the tool when it reaches the mating face. The arm then follows the blank as it is being ground and retracts when the grinding is finished. The Tailstock advance (towards the tool) or retraction (away from the tool) is controlled using pneumatics.

The Tailstock is used with the Overhead Top Clamp (Roller and V Steady Support) to give support when needed for blanks over a certain length. It is important to note the Tailstock does not replace the support provided by the Overhead Top Clamp. The Overhead Top Clamp and Tailstock work together for optimal support and best results. The Tailstock can support tool blanks up to 25.4mm (1”) diameter and 380mm (14.1”) long when manually loading. When used with AR300 loader for unattended operation, blank lengths up to 20mm (¾”) diameter and 200mm (8”) long are supported.

The set-up time when changing the arm and live centre (for different size blanks) is less than 15 minutes. This short set up time for the Tailstock means minimal down time and increased productivity. If a customer is grinding a lot of short and long blanks, the quick set-up time of the Tailstock means the user can manage batch sizes efficiently and quickly. The Tailstock is provided with different size arms to engage the work piece at distances of 90mm (3.5”) to 360mm (14.1”). Both conical and flat end face blanks using different centres can be supported. The force the Tailstock applies on the tool can be adjusted using different force settings. The operator can choose units in either kilograms, pounds or newtons.

The whole assembly can easily be removed from the machine base when not in use and is designed to be refitted with minimal set up. As the Tailstock is a precision piece of equipment, a robust carry case is supplied to make sure the product is well maintained and parts are not lost. The carry case includes all the compartments for the securely holding the centres, carriage arms and set up tooling during transportation. The Tailstock can also be retrofitted for customers with existing CPX Linear machines.

27 October 2020