E-Sharp News

June 2012

The 'FastLoad' automatic loader is now available for the popular FastGrind tool grinder. The FastLoad is ideal for both manufacturing and regrinding applications. This very affordable loader option is available with all new FastGrinds, or for retrofitting to existing FastGrind machines.

The FastLoad provides customers with a low-cost automation solution, which has been optimised for the highest volume diameters and lengths. It has a capacity range of up to 245 tools and a load cycle time of 20 seconds. In addition, there is no need to change gripper fingers between batches, which further maximises productivity levels.

How is the FastLoad so Affordable?

Because the FastLoad is completely contained within the machine canopy and uses the existing machine axes for pallet movement and tool loading.

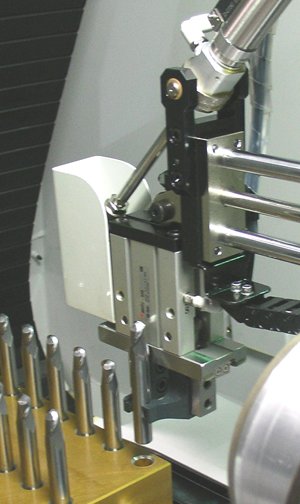

The pallet is attached to the side of the Z-axis saddle and a retracting arm is installed on the machine column. The arm swings down into place to load and unload the blanks and tools, then retracts to an upright position during the grinding process. Access to the loader is through a door in the side of the machine canopy, although the operator can also reach the first tools of a batch through the machine operator door.

View of the FastLoad loader inside the FastGrind machine

Set, Check and Forget

The FastLoad is quick and easy to set-up, which is necessary in today’s demanding production environment and fast tooling turnaround. The pallet layout is simple, it is divided into two sections, one for blanks (pick-up) and one for finished tools (store). The pick-up and store sequence operates from the outside to the inside of the pallet as depicted below. Because the first tools ground in the batch are stored within reach of the machine operator’s door, the operator can easily remove and check them for accuracy without having to use the loader access door.

Pallet loading sequence which identifies the store and pick-up positions, viewed from above the loader

Flexible Software

Loading parameters such as tool pick-up height, or collet insertion length, are controlled by the LoaderMate software. The software also provides the flexibility to include multiple tool types within a pallet. Separate iGrind grinding files (tool groups) can be associated with every different tool type within a pallet. This facilitates the inclusion of different tool types and operations within the one pallet.

Specifications on the FastLoad are listed below. Contact your ANCA dealer to find out more about ANCA's latest development in automation.

Technical Specifications

• Min tool diameter = Ø3mm

• Max tool diameter = Ø20mm

• Max tool head diameter = Ø25mm (1")

• Range of tool length = 30mm (1.2") – 150mm (6”)

• One gripper set covers the entire diameter range

• Loading time is 20 seconds

• Loader capacity:

| Tool Diameter |

Pallet Capacity |

| 3 mm |

245 |

| 6 mm |

156 |

| 12 mm |

68 |

| 16 mm |

42 |

| 20 mm |

36 |

12 June 2012