E-Sharp News

December 2011

I Holland is a UK supplier of punches and dies to global producers of pharmaceutical tablets who is using the TX7+ to improve their punch grinding manufacturing process. I Holland also applies its Tabletting Science to the manufacture of punches and dies for the production of Detergent, Cosmetic, Veterinary and Confectionary products such as Tic Tacs.

Operator, Lee Marsden and Senior Operations Manufacturing Manager, John Woloszczak of I Holland, UK

Committed to Innovation

I Holland is committed to the development of innovative materials and products with a dedication to quality, innovation and the understanding of tabletting science. They have conducted extensive research into factors such as the material science of various coatings, metals and tooling maintenance.

I Holland have a high output of punch tools and have targeted an increase of 30% for this year. Before they purchased TX7+s, I Holland have used ANCA PGX dedicated punch grinders to help achieve their stringent quality standards and high output, and have been very satisfied with their performance.

I Holland Save Time and Money With Multiple Wheelpacks

‘This year', as John Woloszczak explains, ‘we took delivery of two new TX7+ machines as the TX7+ offered us some advantages such as more than one wheel pack so we could grind the neck with a coarser wheel and the head with a finer wheel as the surface finish is critical on the head. This saves us money in wheels and time with one set-up. The smaller grinding wheels used on the TX7 also made them cheaper. An unexpected benefit was that one operator could now easily lift the wheel packs safely so set-up and mounting was only 2-3 minutes instead of 15-20 minutes.’

The tablet tooling manufactured by I Holland often require grinding of multiple features, such as the long neck relief behind the wider punch head. In a conventional punch grinding approach, where only one grinding wheel is available, one of two approaches had to be taken. Either grind the punch with a single grinding wheel that was graded to suit the finest surface finish requirements on a particular punch – wasteful if the rest of the punch requires only rough grinding. Alternatively, different features would be ground in separate set-ups – wasteful in terms of operator and machine time. Because the TX7+ offers multiple wheelpacks in the same set-up, I Holland can now set up dedicated grinding wheelpacks for each operation.

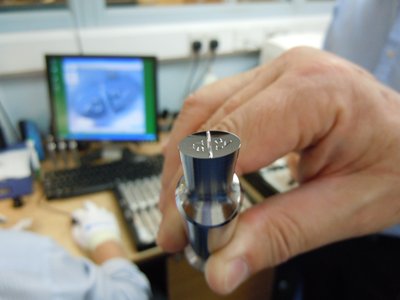

Blank tool and finished punch manufactured by I Holland on the TX7+

How the TX7 is Providing Punch Production Improvements for I Holland

‘We were unsure how the ANCA TX7+ would compare to our PGX in terms of productivity’, shared Woloszczak, ‘but we have found that the TX7+ has actually provided us with opportunities to improve our work processes and easily matched the productivity. Because the smaller wheel packs are cheaper to buy we have changed our set-up process so that we keep dedicated wheel packs in stock for the next punch that requires that form instead of re-dressing wheel profile each time we change punches. This saves us production time and money, and makes us more flexible for smaller batches.’

| |

Conventional punch grind

(e.g. ANCA PGX) |

Grinding punches

on the ANCA TX7+ |

Set-up time

(from very beginning) |

2-3 hours |

15 minutes |

| Cycle time |

27 minutes |

15 minutes |

| Grinding wheels |

Conventional abrasives |

Super abrasive |

Comparison of set-up and grinding cycle times between TX7+ and traditional punch grinding machines

for grinding a Tic-Tac (confectionary) punch

Another benefit that I Holland have found with the TX7+ over traditional punch grinding machines is that it doesn’t leave a reversal mark in the middle of long flat punch faces. This reversal mark, when it is present, is not usually measurable (less than 1 micron) but is a cosmetic defect that customers understandably don’t like. It is not an issue with the TX7+ because it is a 5 axis grinding machine that uses its linear Z axis to travel the full length of a flat punch face. It is the traditional 3 axis punch grinding machines that require a C axis reversal in the middle of a flat surface that have this issue.

Tablet punch manufactured by I Holland on the TX7+

Woloszczak advises ‘I Holland is committed to continuous improvement and with the extra features the TX7+ has, such as 5 axes, multiple wheelpacks and smaller wheel; I’m sure we will continue to find ways to save time and money through tweaking things such as set-up. ‘

Duncan Thompson, TX7+ Product Manager adds, ‘It is great to see companies such as I Holland achieving such production improvements through upgrading from traditional punch grinding technology to the latest in tool grinding technology such as the TX7+. When we first introduced the punch grinding application on the TX7+ we conducted many months of research to fine tune the process. We were able to consistently achieve as good or higher metal removal rates using 8” (200mm) CBN wheels as what was achievable using the traditional large Aluminium Oxide wheels on the PGX.’

‘The other significant benefits of winning over punch grinders, such as I Holland, include the flexibility of using the TX7+ for other types of special punches and grinding operations. Typical 3 axis punch grinding machines are only capable of grinding the OD of standard form punches. With the 5 axis TX7 other grinding operations, such as end face whisper, shear and roof top angles, can be performed. Additionally, having 5 axes means the TX7+ has the flexibility to tackle key hole punch grinding, for which we have a dedicated software package. This opens up a completely new segment of the punch market to manufacturers.’, shared Thompson.

I Holland’s experience with punch grinding on the ANCA TX7+ is further confirmation to us that there is now a better way to grind punches than using a dedicated punch grinder – ANCA’s TX7+.

Visit the I Holland website

2 December 2011